Established in 2020, Copner Biotech is a biotechnology company based in Ebbw Vale, Wales,

with its focus in 3D cell culture and associated technologies. What started as an initial

concept of next generation 3D modelling and printing technology, has gone from strength to strength,

creating an impressive portfolio of technologies,

products and services to the 3D cell culture and bio printing markets.

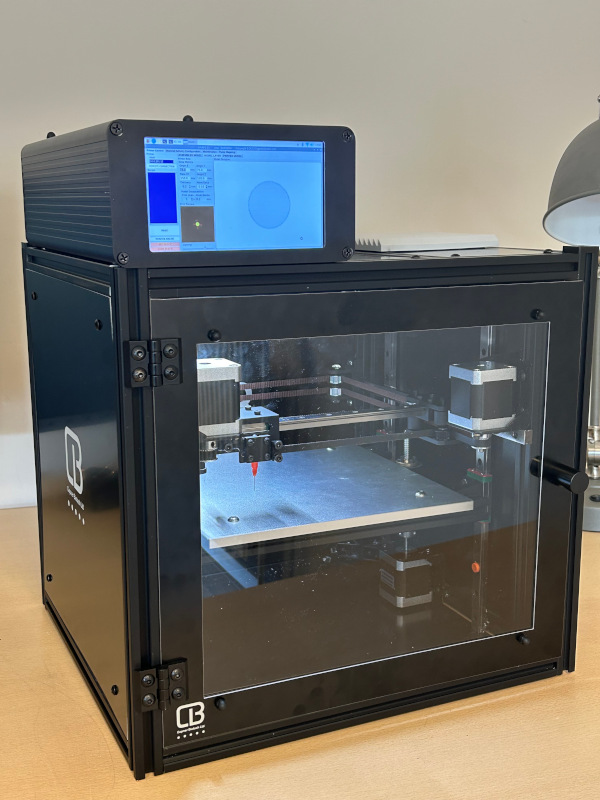

GRAPE S1 4D

Bioprinting Approach

Copner Biotech’s novel approach to bioprinting couples microfluidic droplet deposition with raster-style,

sequential printer head movement. This method of deposition is firstly optimised to the user’s own BioINKs

via our, ‘droplet optimisation protocol’ before users can print personalised 3D constructs.

Microfluidic droplet deposition performed in this manner unlocks a new level of precision and control

during the bioprinting process.

User derived BioINKs

GRAPE S1 4D prints using user derived biomaterials collected from an microfluidic reservoirs, allowing users

to utilise biomaterial/cell combinations (BioINKs) of their choice. This unique ability of GRAPE S1 to allow

user’s own materials has opened a new level of bioprinting freedom, empowering the research community

to push the boundaries of 4D extrusion bioprinting further than before.

Environment

GRAPE S1 4D provides a cleanroom type environment employing multiple configurable temperature zones

to optimise your biofabrication process.

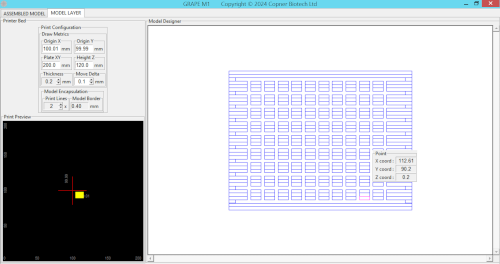

Next Generation Software Control

Whilst other bioprinting systems rely on STL files and g.code, Copner Biotech’s next generation

bioprinters utilise graphical rectangular actual positional encoding GRAPE® files. GRAPE® was developed

to address the key issues associated with STL and g.code procedures currently used in the market today.

These issues include, but are not limited to, troublesome data approximations, modelling anomalies

and low levels of precision in bioprinted constructs.

Our novel and proprietary GRAPE® 3D modelling format allow users to model and print highly precise 3D

constructs, with high batch-to-batch consistency. With our next generation 3D modelling software,

users can design and create complex, microarchitectures directly applicable to 3D cell culture and

tissue engineering applications. From here, GRAPE® files are directly read and printed by the GRAPE S1

system, cutting out the need for tedious and troublesome slicer software.

Enables users to print complex microarchitectures optionally employing different BioINKs for some or all

of the microarchitecture print layers.

GRAPE® Technology - Renderable Biofabrication®

GRAPE® and Renderable Biofabrication®

are trademarks registered with the United Kingdom Intellectual Property Office (UKIPO)

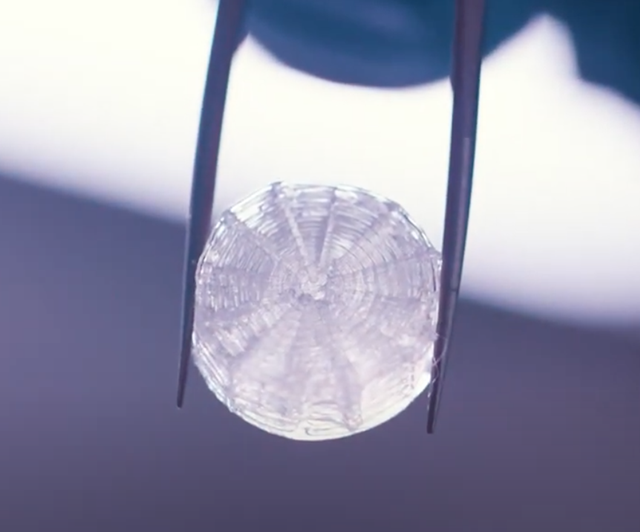

3D PETG Cell Culture Scaffolds

Traditionally, mammalian cells are grown in a 2-dimensional environment,

such as petri dishes, but this is not without its setbacks, namely the

forced polarity that cells undergo due to the nature of the culture environment.

Cells grown 3-dimensionally exhibit more physiologically relevant characteristics.

Copner Biotech's state of the art design and manufacturing process enables 3D cell

culture scaffolds to be produced based on concentric shape constructs, such as circles,

providing a consistent variability of pore size (heterogenous pore size and distribution)

emanating from the centre to the periphery of scaffold.

The effect is to provide clear regions of the scaffold where cells will have more favourable

nutrient and oxygen exchange (periphery)and areas not so (centre). Such constructs better

represents physiological conditions in the body providing tangible experimental advantages

for research in fields studying cell microenvironments.

Mission

Copner Biotech's goal is to ultimately dominate in the bioprinting market.

We will do this via innovative, industrial collaborations with like-minded companies

already in this space, utilising our novel GRAPE® technology. We continue to work upon and develop our

existing technologies, in the software and 3D printing hardware space, to create competitive products for the Global Market.

GRAPE® Data Format and method of 3D Modelling

Our novel and proprietary GRAPE® 3D modelling format enables users to model and print highly

precise 3D constructs, with high batch-to-batch consistency.

With our next generation 3D

modelling software, users can design and create complex, microarchitectures directly

applicable to 3D cell culture and tissue engineering applications; for example the

cultivation and subsequent convenient extraction of spheroids.

Spheroids are a type of three-dimensional cell modeling that better simulate a live cell's

environmental; specifically regarding the reactions between cells and between cells

and the matrix.

The efficacy of an original scaffold design has been the subject of a collaboration project with

Swansea University realising fantastic cell culture results. These scaffolds are now available

through life sciences vendors Appleton Woods (UK and Ireland), Lucerna-Chem AG (Swiss)

and ISOGEN Life Science (Benelux and Spain).

Copner Biotech are working with researchers at Cardiff University School of Biosciences

to validate our 3D PETG scaffolds when applied to novel forms of microscopy research.

This collaboration will further establish our 3D PETG scaffold capabilities to be at the

forefront of 3D cell culture technology.

GRAPE® Data Format and method of 3D Printing

Bioprinting is the 3D printing of biological materials, which may also be laden with

mammalian cells. The predominant use of bioprinting is the production of tissue like structures

for drug testing, with more and more large companies looking towards this technology as an

alternative to animal testing.

Copner Biotech’s novel approach to bioprinting couples microfluidic droplet deposition with raster-style,

sequential printer head movement.

This method of deposition is firstly optimised to the user’s

own BioINK via our, ‘droplet optimisation protocol’ before users can print personalised 3D constructs.

Microfluidic droplet deposition performed in this manner unlocks a new level of precision and

control during the bioprinting process.

GRAPE M1 Modelling Software Launch : Copner Biotech's GRAPE M1 3D modelling software comes

bundled on purchasing any of our bio printers; for example GRAPE S1. GRAPE M1 outputs 3D models in both

GRAPE and STL model data formats enabling GRAPE® technology to be applied to and potentially improve the

perfomance of third party 3D bio printers. GRAPE M1 is now available as a standalone product to purchase.

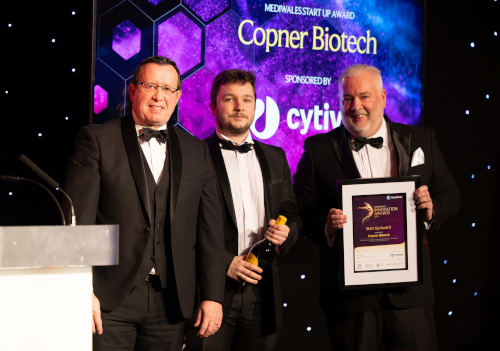

MediWales Innovation Start-Up Award 2022

Copner Biotech attends the MediWales 2022 Innovation Awards ceremony in Cardiff and were

proud to walk away with the prestigious Innovation Start-Up Award.

On receiving this award we looked back on our achievements over the last year both in

terms of high growth and ground breaking innovation; culminating in this recognition from MediWales.

MediWales Innovation Award 2023

Copner Biotech's Additive Manufacturing using low viscosity biomaterials technology

scoops top Innovation Award at MediWales Innovation Awards 2023 Ceremony held in Cardiff.

This prestigeous Innovation Award was supported by the Development Bank of Wales.

GRAPE S1 4D Desktop Extrusion Bio Printer.

GRAPE S1 4D defines the new benchmark in extrusion bioprinting both in terms of printing accuracy, biomaterial dispensing environment and small bioprinter footprint 450mm height, 385mm width and 350mm depth. GRAPE S1 4D brings biofabrication to your desk enabling the bioprinting of multiple user derived bioINKs within a cleanroom type environment employing multiple temperature zones. GRAPE S1 4D employs microfluidics and does not require any external compressors and/or laboratory modifications.

Accelerate Healthcare Technology Centre Research Collaboration.

Copner Biotech's CEO and Accelerate Healthcare Technology Centre scientists complete their

collaborative research on the efficacy of our 3D PETG cell culture scaffold technology.

Accelerate Healthcare Technology Centre .... "this novel 3D cell culture platform offers enormous potential for

research into multiple cell types, including: cancer cells, cardiomyocytes,

fibroblasts and liver cells. Experts believe that the applications for this

product are genuinely limitless, and the reality is that researchers are routinely

discovering new opportunities provided by these advanced scaffold designs"

CEO and CTO Receiving MediWales Innovation Start-Up Award 2022.